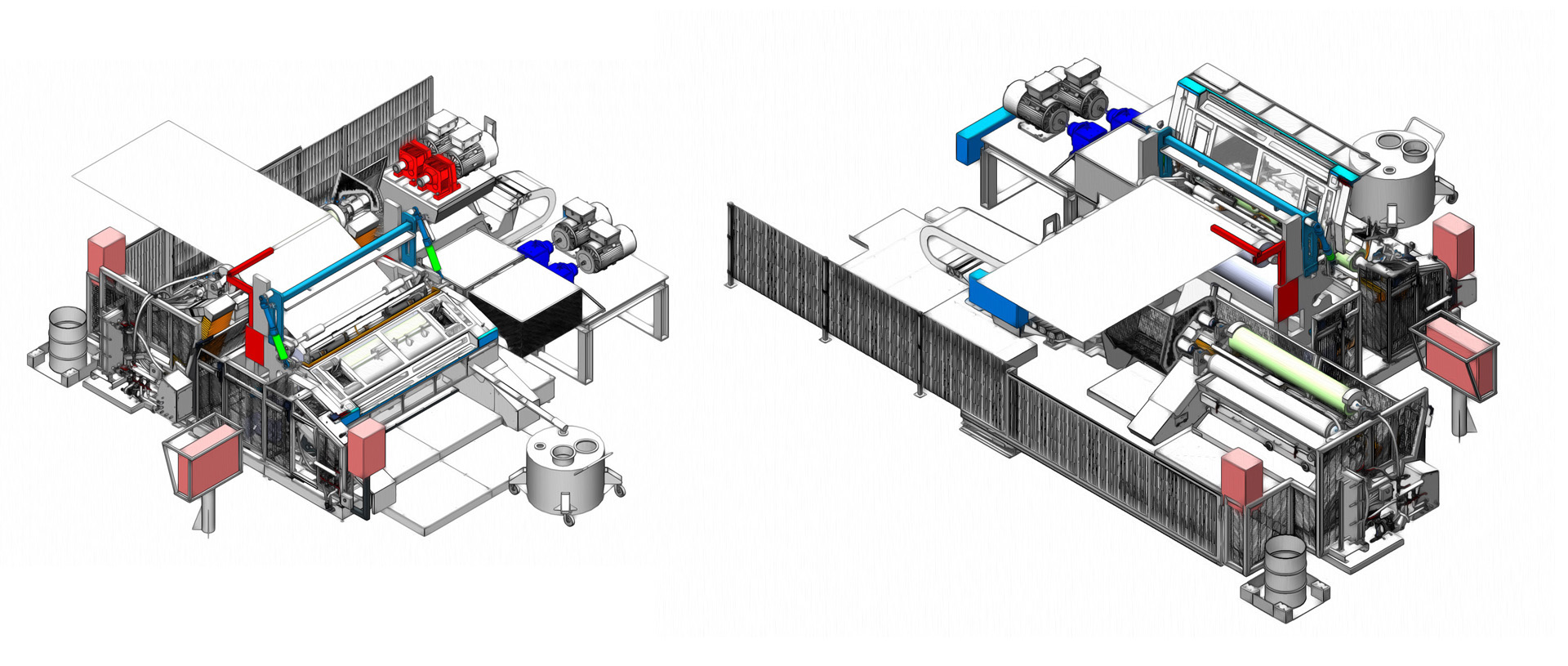

Active in the aluminum sector, a European multinational turned to KARL HUGO’s expertise for the complete renovation of an S-shuttle coil coater.

While the main structure was preserved, the mechanical roller drive coupling system was completely redesigned. KARL HUGO’s engineers developed a unique automatic coupling capable of transmitting extremely high torques while ensuring maximum safety and ease of use for the operator.

A tailor-made engineering project

At the heart of this modernization lies an innovative torque transmission interface. “We coupled the rollers faster, safer, and more ergonomically,” explains Thomas Reuter, Project Engineer. “This toothed pneumatic device was specifically designed for this project. It allows the transmission of very high torques while ensuring optimal alignment and enhanced robustness.”

More safety, less effort for the operator

Thanks to the automatic coupling, the operator no longer has to lift heavy components or manually handle the drive shaft. The rollers are positioned using the overhead crane as before, but the opening and closing of the system is now fully pneumatic. “This machine features a full head-lowering system to facilitate roller cleaning during paint changes,” notes Jean Koninckx, Engineering Manager.

“The new lower head is mounted on a cantilevered trolley system on the central frame. This ensures time savings during setup and enhanced safety for operators.” Moreover, all operational steps of the coupling are monitored by sensors - an active safety approach that anticipates risks and provides continuous system oversight.

A bespoke solution for increased power

The upper and lower heads of the coater were renovated, while the central section was retained. The new heads were designed to improve cleaning access, featuring a shuttle-type structure and a mechanical retraction of half a meter. “With a strip width of over 2100 mm and a strip outlet height of more than 2500 mm, this machine operates at a speed of 300 meters per minute,” explains the Project Engineer. The increase in motor power necessitated the development of a more efficient coupling, capable of keeping up with the high-speed demands.

Although designed for this project, the solution is not limited to a single application. Thanks to its modular and adaptable design, it can be easily integrated into other existing equipment. “This system can meet similar needs for other clients facing challenges related to high torque, limited access, or enhanced safety requirements.”

This new toothed automatic coupling is far more than a mechanical component - it's the result of high-level engineering, designed for real-world applications. It combines performance, ergonomics, and safety.